Why MIG MAG with double pulse?

We constantly have in mind the continuous improvement process whereupon we are trying to meet your expectations within quality and lowering production costs. As far as quality is concerned, we fulfill international standards requirements concerning the structure specified in the PN EN ISO 3834-2 standard. Additionally, we focus on high visual quality of welds. Many of you choose the TIG method due to the quality of welds, however applying the TIG method is related to lower efficiency as compared to the MIG/MAG methods applied.

Therefore, we asked ourselves a question:

Is there a welding method which allows to achieve high visual aesthetics of welds and higher efficiency as compared to the TIG method?

Yes – the desired solution is the MIG/MAG method with double pulse!

Welding with the use of MIG/MAG method with double pulse we are able achieve a high level of weld bead (scale effect). Additionally, the application of automatic feeding of wire has impact on the efficiency of welding. Structures welded with the MIG/MAG method are made faster, therefore the manufacturing costs are lower.

The MIG/MAG method with double pulse allows current pulsing regulation and adjustment of wire feeding speed thanks to which a weld appearance is improved.

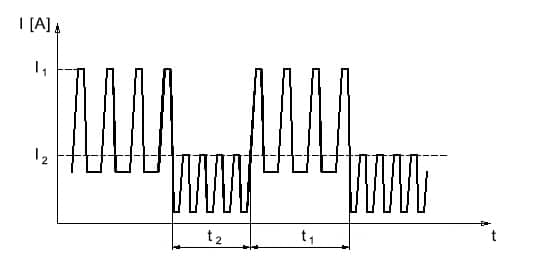

While welding with the use of the MIG/MAG method with double pulse, current pulses occur in two ranges. Sequential circuit of our welders automatically joins two levels of pulses: hot I1 and cold I2.

Benefits of using the MIG MAG with double pulse:

1. Welding with the use of the MIG/MAG method with double pulse is faster as the TIG method

2. Welding with the use of the MIG/MAG method with double pulse achieves as high aesthetic standards as the TIG method.

3. Welding with the use of the MIG/MAG method with double pulse causes smaller deformations as compared to the TIG method.

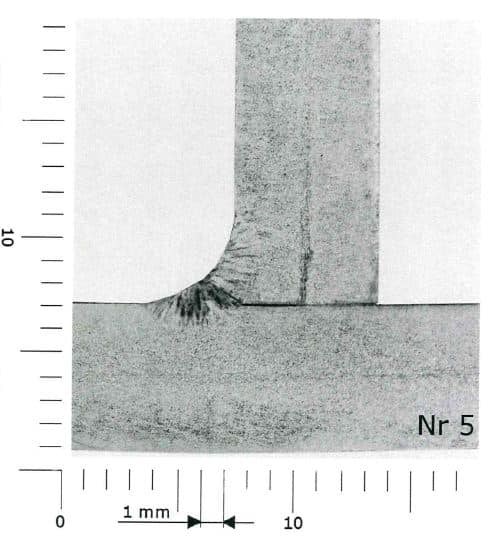

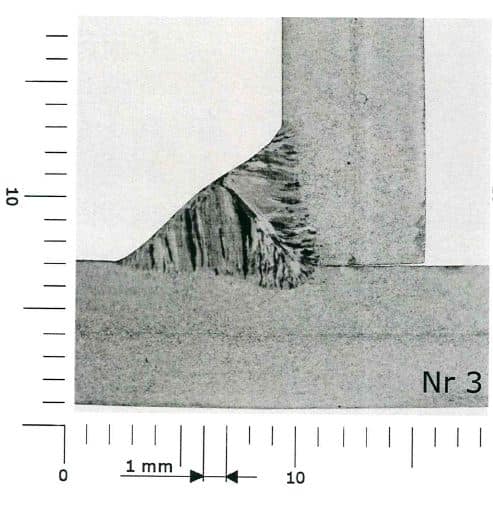

We have prepared samples of welding with the use of the TIG and MIG/MAG methods which we later submitted to macroscopic tests. The first picture shows connections made with the use of the TIG method, while the second one shows connections made with the MIG/MAG method with double pulse.

Download a free Base Group PDF brochure: MIG-MAG welding in TIG quality

In case of any questions do not hesitate to contact us! Feel free to make enquiries relating to metal structures!

Click “Like” button on our Facebook profile and follow us! www.facebook.com/BaseGroupKoszwaly